Expertise

Testing & Maintenance

Ensure your systems run safely and efficiently with our comprehensive testing and maintenance services.

Watson Electrical

Our Preventative Maintenance Programs focus on regularly inspecting, testing, and adjusting electrical equipment to prevent issues and extend its lifespan. Each program is fully customized to meet the unique needs of your company and facility, ensuring optimal performance and compliance. Our expert technicians have delivered numerous solutions that keep clients aligned with OSHA and NFPA standards. Proactive maintenance helps reduce operating costs, meet insurance requirements, and minimize business interruptions — protecting your electrical system, facility, and employees.

1/

INSPECTION

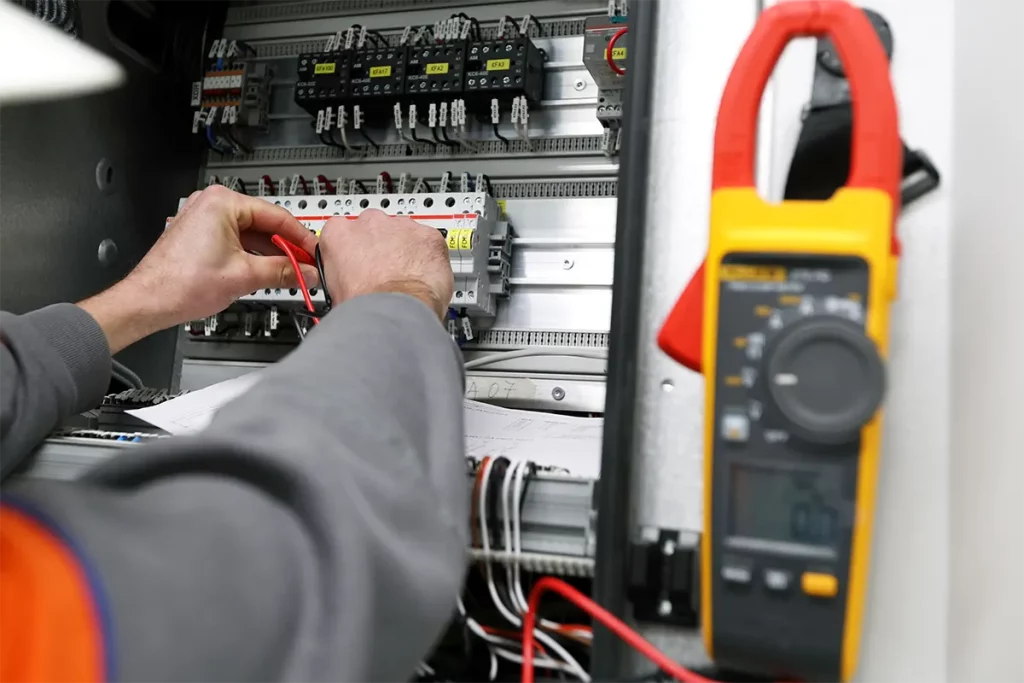

The electrical system is inspected for signs of wear, damage, and loose connections

2/

TESTING

Electrical equipment is tested to ensure that it is working properly

3/

ADJUSTMENT

Electrical equipment is adjusted to ensure it is operating within safe limits.

4/

DOCUMENTATION

The results from the preventative maintenance process are documented so they can be tracked over time.

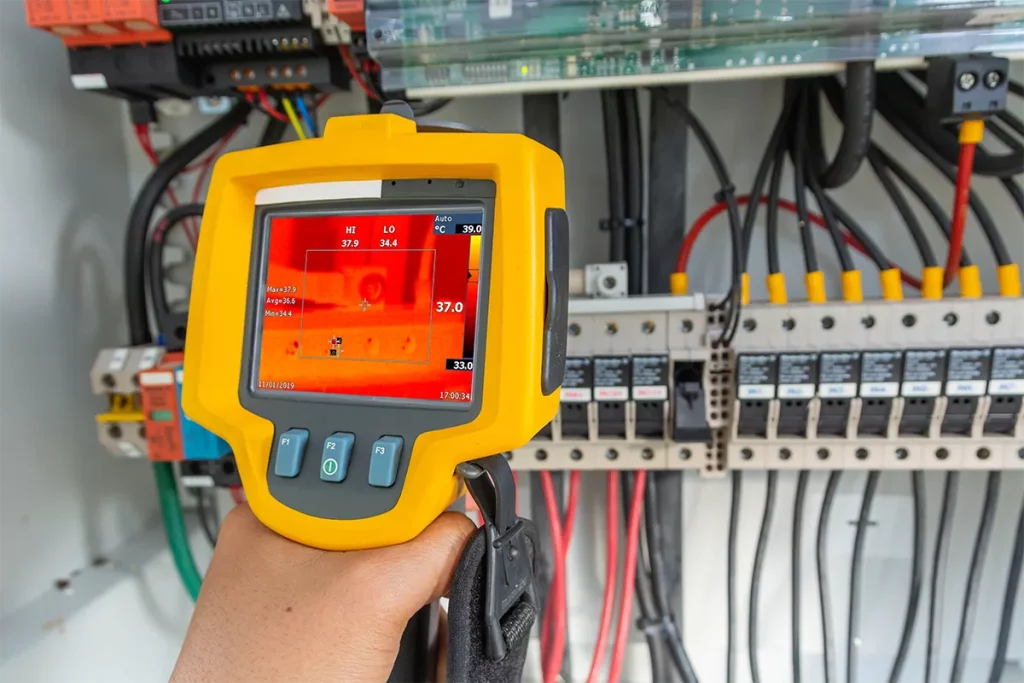

Thermal Imaging

As your electrical distribution system ages, hidden issues can put your operations at risk — but infrared scanning uncovers “hot spots” before they become costly problems. From overloaded breakers and loose connections to open circuits and electrical faults, our advanced inspections catch issues early, keeping your systems running safely and efficiently. With our infrared services, you can extend equipment life, minimize downtime, reduce repair costs, and keep production flowing without disruption.

Protecting What Matters Most

Arc Flash incidents can occur due to improper tool usage, lack of maintenance, equipment corrosion, or insufficient safety training, potentially causing severe equipment damage or even fatal injuries. To prevent such hazards, the National Fire Protection Association (NFPA) 70E standards require facilities to conduct an Arc Flash Risk Assessment to identify risks and determine necessary protective measures. Watson offers comprehensive Arc Flash Risk Analyses, helping ensure your facility’s safety procedures align with NFPA and Occupational Safety and Health Administration (OSHA) regulations. Through our detailed electrical safety inspections, our experts can assist in developing and maintaining a thorough, cost-effective Arc Flash Protection Plan tailored to your operations.

1/

Generate a Written NFPA 70E Safety Plan

2/

Train Employees in NFPA 70E

3/

Generate and Post an Electrical One-Line Diagram

4/

Perform an Arc Flash Study and Apply Labels

5/

Understand and Provide the Proper PPE

6/

Perform Regular Maintenance on Electrical Equipment

Electrical Distribution Maintenance

With new technology come new electrical demands — from LED lighting to variable frequency drives and other advanced equipment, your electrical distribution system can experience unique stresses. Watson’s metering and testing services help identify and isolate potential problems, pinpointing their causes before they impact operations. Our metering capabilities allow us to perform a wide range of tests and analyses, including:

This proactive approach ensures your systems operate safely, efficiently, and reliably.

TEGG Service Contractor Network

As a certified TEGG Service Contractor, our team is highly trained to deliver the TEGG System — a comprehensive preventative and predictive maintenance program for commercial and industrial electrical systems. Unlike traditional methods, TEGG testing is performed while systems are energized, providing real-time, accurate data on system and component performance. As part of the TEGG network, our customers have access to ASNT Level 3 IR Certified Technicians, ensuring expert analysis. This advanced approach captures critical information previously impossible to obtain, helping clients avoid costly downtime while gaining a precise view of their electrical infrastructure.

Contact Us

Ready to start the conversation around your next Testing and Maintenance project? Reach out today!